- Contact Person : Mr. Yang Jack

- Company Name : Zibo Doubang Chemical Co., Ltd.

- Tel : 86-531-81183277,13969116032, 13864317703

- Fax : 86-531-8118277

- Address : Shandong,Jinan,Rom 303, 230 Shanda road, Jinan

- Country/Region : China

aluminium Hydroxymethylphenylphosphinate

Detailed Product Description

Chem. Group: Phosphinates Supply Form: white powder

Chemical Name: aluminium Hydroxymethylphenylphosphinate

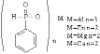

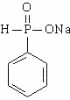

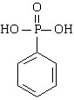

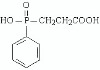

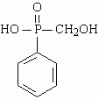

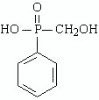

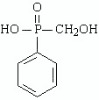

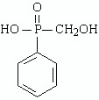

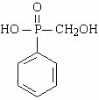

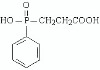

Chemical Formula:

Product Description

FRPAA is a non-halogenated flame retardant based on organic phosphinates. The product achieves its flame retardant effect through intumescence. The thermoplastic material foams and crosslinks on exposure to flame and forms a stable char at the surface acting as a barrier. The protective layer provides a heat-insulation effect, reduces oxygen access and prevents dripping of molten polymer.

Delivery Specification and Technical Data

Phosphorus %(w/w) 16.2-18.1%

Water / Moisture %(by wt.) max. 0.5

Density g/cm³ approx. 1.42 at 20 °C

Bulk Density kg/m³ approx. 400

Decomposition Temperature °C > 340 (DTA/TG)

¹) The product is constantly monitored to ensure that it adheres to the specified values.

²) The technical data are used solely to describe the product and are not subject to constant monitoring

Applications

FRPAA was developed especially for use in polyamides. It is suited for both glass-fibre-reinforced and unreinforced grades. The flame retarded polyamide compounds exhibit very good physical and electrical properties.

Formulation

In glass-fiber-reinforced polyamide 6 or 6.6, a dosage of 12 to 18 % (by wt.) FRPAA is usually sufficient to obtain the UL 94 V-0 classification for electrical components (at 1.6 as well as 0.8 mm thickness). Subject to the polymer grade, processing conditions and glass- fibre reinforcement the dosage of the flame retardant may vary.

Processing

Before incorporating FRPAA, it is important to predry the polyamide as usual. If possible, the resulting moisture content should be below 0.1 % (bywt.). Predrying of FRPAA is not necessary. However, predrying(e.g. 4 h at 120 °C) is recommended, if even very low moisture contents must be avoided. The mixing and processing methods customary in powder processing of polymers can be used with FRPAA. The optimum conditions for incorporating should be determined in each individual case. Care must be taken to ensure homogeneous dispersion of all components. The temperature of the polymer melt should not exceed 320 °C.

The FRPAA can also work as starting materials for the preparation of flame retardants for thermosetting resins, such as unsaturated polyester resins, epoxy resins, polyurethanes or acrylates or as starting materials for the preparation of flame retardants for thermoplastic polymers, such as polyethylene terephthalate, polybutylene terephthalate.

Packing: 25Kgs in barrel